I would have taken some pictures, but I sprayed waxoil everywhere and it got a bit messy.

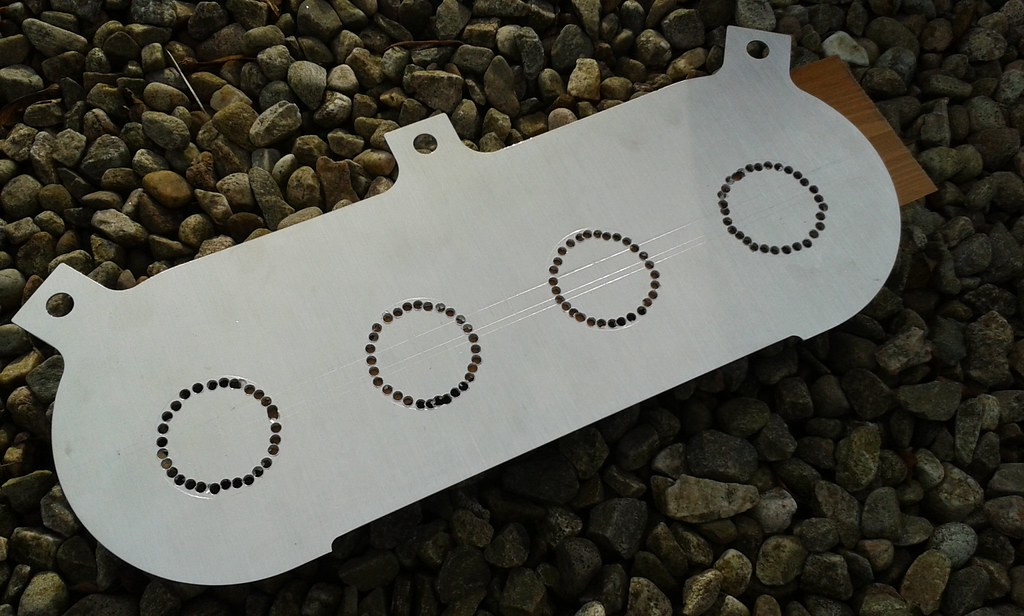

The rings can be used on the underside of the pannel to hold the nuts inplace. As I wouldn't be able to get a finger onto the nuts from the underside, I used a bit of Evostick to glue the nuts into the ring as they were a bit too loose and I could guarantee that the sixth nut would drop out if I had tried without glue.

The complete ring wouldn't quite fit down through the hole, so I cut out a section between two of the nuts making it into a C shape. This allowed me to thread the ring down through the hole, which just left keeping it inplace as the next hurdle :?

With the ring held inplace, I threaded some string down through one of the 4.5mm holes in the bonnet and nut, then back up through an adjacent nut and hole, giving two ends to pull on. Repeat for a pair of nuts on the opposite side so you now have four ends of string.

Now, pulling on the four ends of string holds the ring to the under side of the bonnet skin and leaves two bolt holes free

Passing the ends of the string through the relevent holes in the Aerocatch, drop the catch into place. Pull on the string and wiggle the ring into position so you can fit the two bolts that are free, leaving them slightly loose for now. Now the ring is loosely bolted inplace, pull the lengths of string out and fit the remaining four bolts. Tighten up all six bolts

Adjust the height of the pins so the catches are properly secure and the jobs finished :mrgreen: